An Enduring Commitment to Environmental Responsibility

Masonite has been a leader in Environmental Responsibility from the very beginning. In 1924 William H. Mason’s ground-breaking discovery–that post-industrial wood chips could be reconstituted and used to create building material–became one of the blocks on which Masonite was built.

At Masonite we are committed to trying to leave the planet much as we found it. For example, no old growth timber is harvested solely for the production of Molded Panel Doors from Masonite. By-product wood chips are a vital ingredient in many of Masonite’s doors and timber that is used comes from sustainable, managed forests. In addition, our doors are made in manufacturing facilities designed to be easy on the environment.

It’s logical that the longer a door performs the less the stress on the environment. Therefore, all materials – wood, fiberglass, steel or composites – are engineered and selected for lasting durability.

If you are looking to conserve our natural resources, or if you are seeking an industry certification, Masonite has the answer. With Masonite you never have to sacrifice superior quality for environmental stewardship.

Masonite’s Green Council

This council helps define, develop and implement Masonite’s Environmental Policies & Strategy. A cross-functional team, the Green Council also generates new product ideas and reviews service and policy opportunities. These will further solidify Masonite’s position as a Green leader in the global marketplace.

Masonite’s Manufacturing Impact

We employ environmental management systems intended to ensure compliance with all environmental laws and regulations. As well, we pride ourselves in workplaces that are safe and healthy.

Masonite’s Energy Conservation

ENERGY STAR is a Department of Energy program that rewards consumers and builders for selecting energy efficient products. Masonite Steel and Fiberglass Doors can be assembled to qualify for ENERGY STAR. More on Energy Efficiency

Masonite’s Renewable Materials

We are reducing our environmental impact by using wood fiber from well managed forests and other renewable biomaterial, such as wheat straw, in all of our interior door products.

Masonite’s Recycled Content

Recycling has a significant positive effect on the environment. Where possible, Masonite utilizes recycled materials in our doors. As an example, the interior molded door facings that Masonite manufactures contain post-industrial wood chips, a key ingredient. In addition, Wheatcore, particleboard and fiber products all have recycled content.

Masonite’s Logistics

Recognizing that transporting products consumes energy, Masonite has created regional manufacturing plants thus minimizing the amount of travel necessary to provide our superior quality doors to our customers.

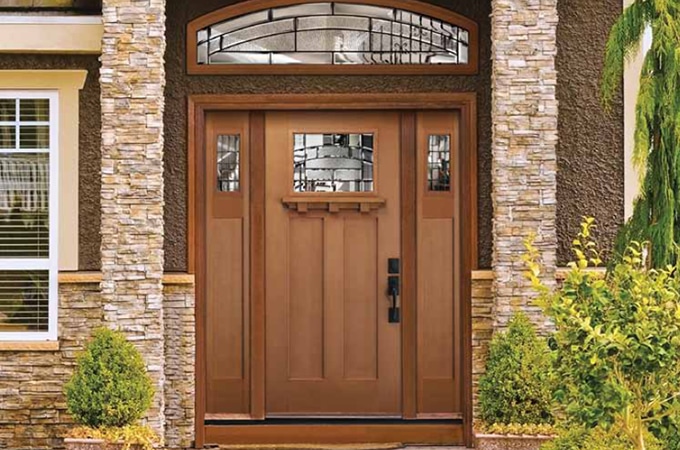

Masonite’s Environmentally Beautiful Products

From the homeowner that is environmentally conscious to the architect that is designing a project to achieve an industry certification, research has shown that the market clearly has a desire for Green products. Preserving the environment does not need to require that you sacrifice design or quality, at least when Masonite doors are concerned. Masonite continues to offer many Environmentally Beautiful Doors that are truly environmentally responsible and can also provide a solution for “Green” specifiers by contributing to industry certifications. The Safe ‘N Sound® and Safe ‘N Sound® Emerald™ are the most recent products to be introduced that can contribute to industry certifications.

Visit Masonite to see their full line of sustainably manufactured doors. And check out Masonite Architectural to see their whole product line.

Products featured on Elemental Green have not been fully vetted for accuracy of claims. We encourage consumers to do their own research to find products and companies that align with their values. Additionally, product and brand mentions on Elemental Green do not imply an endorsement unless specified otherwise.